Techniques, Processes, and Engineering Principles

The concept of well patching is integral to maintaining and repairing wells, ensuring their longevity and functionality. A patch, by definition, is a piece of material used to repair tears, cover holes, or strengthen weak areas. This broad definition allows for different interpretations of well patching methods and materials used to patch them.

Well patching can involve several techniques, depending on the contractor doing them. One common method involves lining an area in the well with smaller casing (called a liner). This often requires downsizing the pump and the water pumping rate. Another method stretches smaller pipe to line the inside of the well. The drawback of this method is that the smaller pipe doesn’t gain rigidity due to metal memory and over time wants to return to its original size. The best method is to use a metal patch specifically design to seal and strengthen the well’s existing casing.

Lining an area in the well with smaller casing is a straightforward method, but it does come with its challenges. Gravel needs to be placed in the void space between liner and patch to keep unwanted water from traveling up or down. The smaller diameter inevitably means that the pump and the associated water pumping rate need to be adjusted to accommodate the reduced space. However, this method is often done for its simplicity or when the contractor does not have access to a swaging tool.

Another method involves expanding smaller pipe out to line the interior of a well, which is often accomplished using an inflatable packer (sometimes incorrectly referred to as a swage). Packers lack the pressure capacity required to forge metal and thus cannot permanently bond two metals together. The primary limitation of this technique is related to the phenomenon known as metal memory, which can result in the inner casing being prone to water leakage over time.

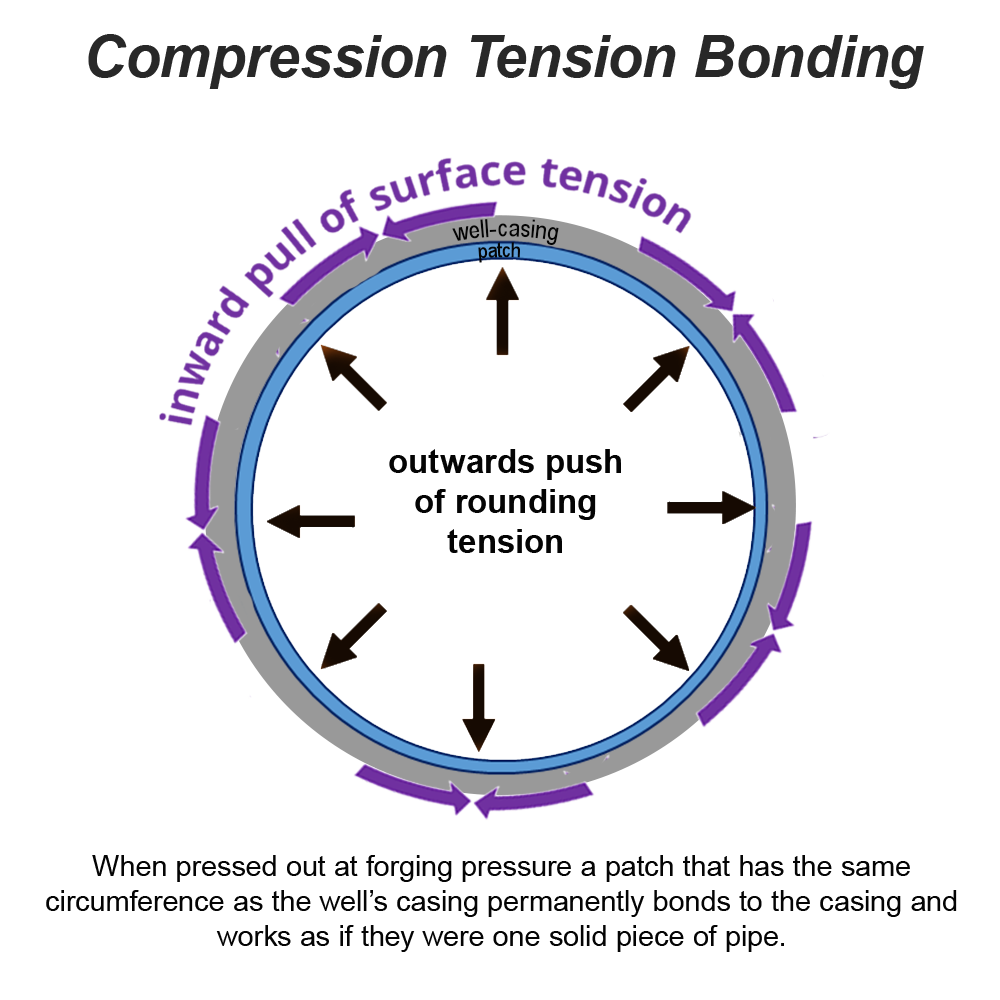

The best method to patch a well is with a hydraulic swage and a specially rolled corrugated or wedge-shaped metal patch that matches the well casing circumference when swaged out. The hydraulic forging pressure permanently bonds the well patch to the well casing. This makes the patch section work as one stronger, more rigid section of well casing.

The science behind hydraulic swaging is a cold forging process that uses hardened steel dies and hydraulic leverage. The leverage turns the pressure psi into tsi (tons per square inch). It is the reaction of the patch pushing out and the well pushing in that permanently joins the two in a compression bond. The engineering principle of pressure bonding states that when two cylindrical pipes are in contact, any movement or flexing of one pipe necessitates a corresponding movement or flexing of the other pipe.

Additional Benefits of well Patching

Swaging in well patches can do more than cover holes, cracks or week areas. The strength of a patch can be demonstrated by applying weight before it is fully swaged. This capability enables a patch to function as both a liner and a screen hanger. An experienced swage operator has the ability to craft a tapered reducer that is sealed at both ends, create a seal at either the top or bottom of a long liner, or replace a failed k-packer. The versatility and durability of well patches contribute significantly to their importance in well maintenance and repair.

Long or stacked well patches can help prevent further deterioration of the well structure, ensuring that the integrity of the well is maintained over a longer period. This preemptive measure can save significant costs and resources that would otherwise be spent on extensive repairs or well replacement.

By effectively sealing leaks and weak spots, well patching also plays a crucial role in maintaining the quality of water extracted from the well. Contaminants from surrounding soil and rock formations can be prevented from entering the well, thereby ensuring that the water remains clean and safe for use.

Well patching is a critical process in the maintenance and repair of wells. Various methods, each with their own advantages and limitations, can be employed depending on the specific requirements of the well. The use of hydraulic swaging and specially rolled metal sections represents the best practice, ensuring a rigid, durable, and effective patch. By addressing weak areas and preventing further damage, well patching helps maintain the functionality and longevity of wells, ultimately contributing to the sustained availability of clean water.

Well patching is a critical process in the maintenance and repair of wells. Various methods, each with their own advantages and limitations, can be employed depending on the specific requirements of the well. The use of hydraulic swaging and specially rolled metal sections represents the best practice, ensuring a rigid, durable, and effective patch. By addressing weak areas and preventing further damage, well patching helps maintain the functionality and longevity of wells, ultimately contributing to the sustained availability of clean water.