The Power of Swaging

Swaging is a forging process that uses dies to reshape metal. Originally used by cable tool drillers to hammer out broken casing, modern swages use hydraulic force for safer and more precise repairs, restoring even the most difficult wells to a usable condition.

Inflatable packers sometime used as swages, would rupture in broken casing or come a part before reaching metal forging pressure. MPXSwages use hardened steel jaws (dies) pushed out by hydraulic leverage. By limiting the push area to a few inches with each push a swage can join and bond metal together stronger the any hot welding can do.

Hydraulic Swage vs. Inflatable Packer

*Hydraulic oil is used because it does not compress or blow by seals at high-pressure operation. Our swages feature closed double-acting cylinders, preventing oil from contacting well water. For environmentally sensitive areas, food-grade hydraulic oil can be used in case of accidental leaks.

Corrugated Patches

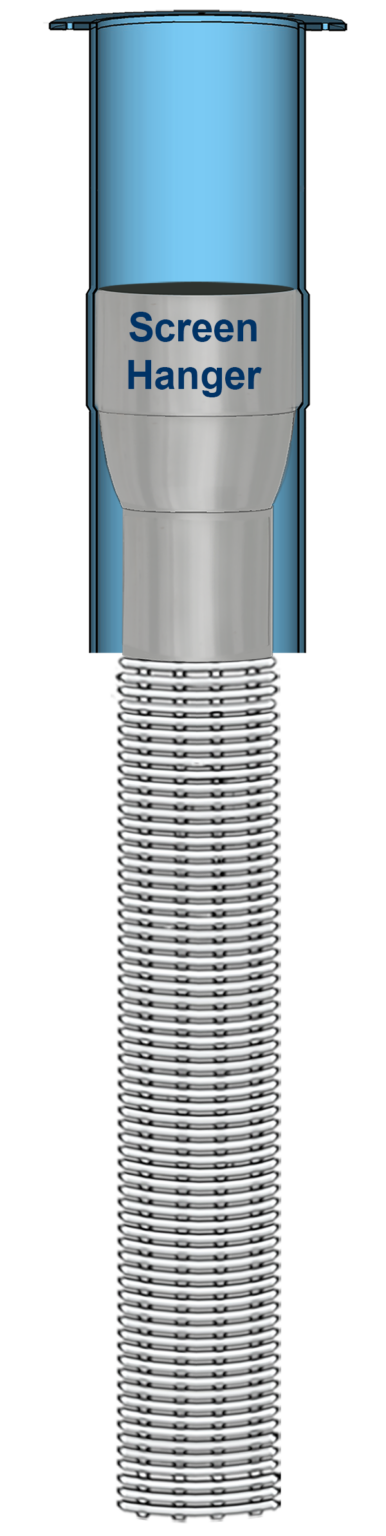

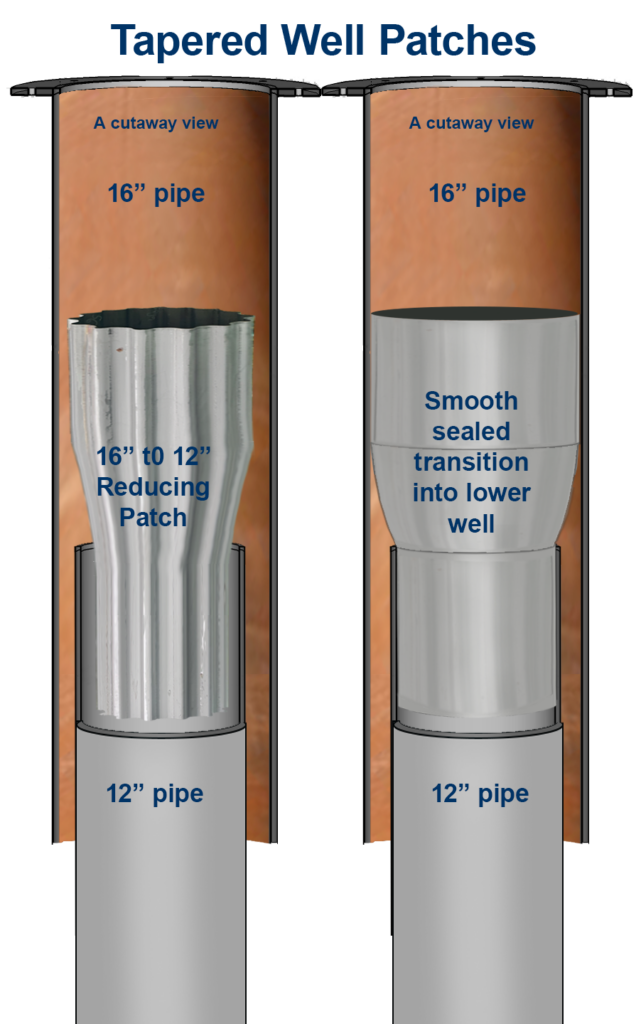

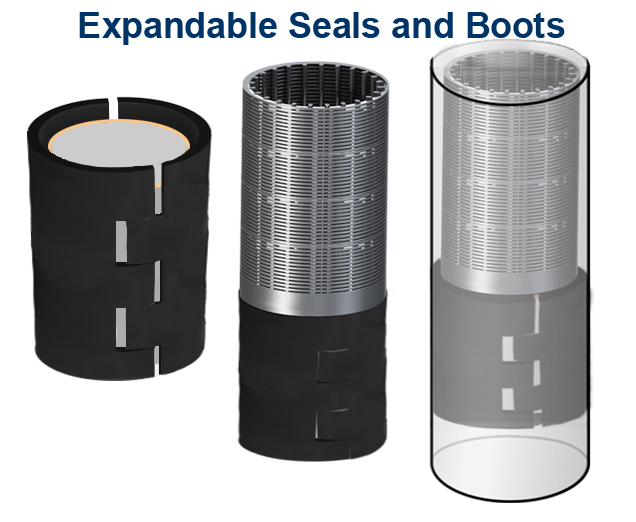

MPXSwages form a solid-state weld between a patch and the pipe in which they are installed. This means they can do more than line the inside of a well with thin pipe. Corrugated patches can be made thin, thick or layered to seal off long areas of missing or deteriorated casing, manufacturer tapered reducers downhole and used to place and seal long liners and screens in place.

Contact Welding—also referred to as solid state or cold welding. Refers to welding at a molecular level through pressure and surface contact. Metal has microscopic peaks and valleys on its surface due to its crystalline structure. When two round metal surfaces that have the same perimeter (circumference) are compressed together their surfaces interlock at the pressure it takes to round them into the same space. They bond from inwards and outwards pressure not allowing either to move, bend or elongate without the other.

A Few Things Patches Can Do:

- Repair holes & breaks

- Seal off jetting water

- Reconnect offsets

- Add stainless steel lining to eliminate erosion

- Repair PVC wells

- Fish out a pump

Well Patching

For more information on swaging Call Bob (916) 765-5221

Bob Guardino

Tel. 916 765-5221

Email: waterwellbob@gmail.com

Mike Guardino

Tel. 916 799-0553

Email: wellboyh2o@gmail.com

We are well repair swaging specialists, that design and build swages that work in 6-inch to 24-inch wells.